One minute to teach you how to choose board-to-board connectors

Hello everyone, I am the editor. There are many types of connectors. Common types include communication interface terminals, wiring terminals, wire-to-board connectors, and board-to-board connectors. Each category can be subdivided into several categories, such as: board-to-board connectors include headers and females, board-to-board connectors, etc.; wire-to-board connectors include FPC connectors, IDC sockets, simple horn sockets, etc. So when choosing a connector, from which angles should we consider a connector suitable for hardware use?

1. Pins and spacing

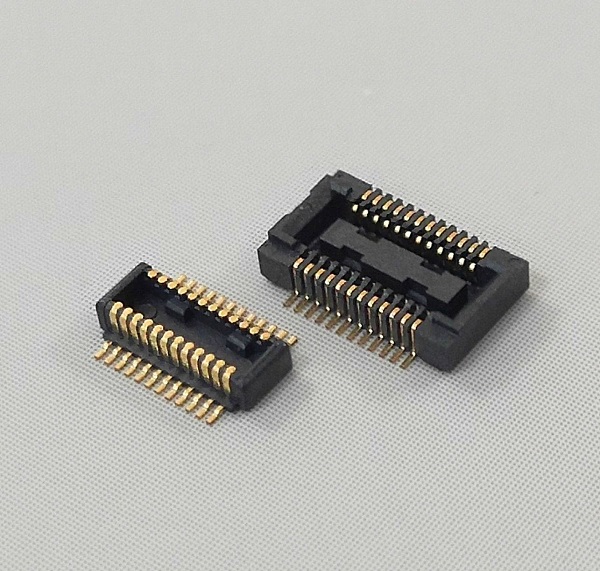

The number of pins and the spacing between pins are the basic basis for connector selection. The number of pins selected for the connector depends on the number of signals to be connected. For some patch connectors, the number of pins in the patch headers as shown in the figure below should not be too much. Because in the soldering process of the placement machine, due to high temperature, the connector plastic will be heated and deformed, and the middle part will bulge, resulting in false soldering of the pins. In the early development of our P800Flash programmer, this header and mother header were used for board-to-board connection. As a result, the pins of the prototype header were soldered in large areas. After changing to 2 pin headers with halved pins, there was no false soldering.

Nowadays, electronic equipment is developing towards miniaturization and precision, and the pin pitch of the connector has also changed from 2.54mm to 1.27mm to 0.5mm. The smaller the lead pitch, the higher the requirements for the production process. The lead spacing should be determined by the company’s production technology level, blindly pursue small spacing

2. Electrical performance

The electrical performance of the connector mainly includes: limiting current, contact resistance, insulation resistance and dielectric strength, etc. When connecting a high-power power supply, pay attention to the limit current of the connector; when transmitting high-frequency signals such as LVDS, PCIe, etc., pay attention to the contact resistance. The connector should have a low and constant contact resistance, generally tens of mΩ to hundreds of mΩ.

BOARD TO BOARD CONNECTORS PITCH :0.4MM(.016″) SMD H:1.5MM POSITION 10-100PIN

3. Environmental performance

The environmental performance of the connector mainly includes: resistance to temperature, humidity, salt spray, vibration, shock, etc. Choose according to specific application environment. If the application environment is relatively humid, the requirements for resistance to humidity and salt spray of the connector are high to avoid corrosion of the metal contacts of the connector. In the field of industrial control, the requirements for the anti-vibration and shock performance of the connector are high to prevent the connector from falling off during the vibration process.

Actual tests show that due to the unique directionality of the socket, this connector has obvious fool-proof effects, small insertion force, moderate separation force, and good plug-in feel, which greatly improves the convenience of plug-in parts.

Connectors, which are commonly called connectors by engineers, are used to connect two circuit boards or electronic devices to achieve power or signal transmission. Through the connector, the circuit can be modularized, the assembly process of the electronic product can be simplified, and the product can be easily maintained and upgraded. For modular circuits, the selection of connectors plays a decisive role.