What should I pay attention to when storing board-to-board connectors?

Insulation inspection rules for board-to-board connectors: the same type of insulating material produced by qualified suppliers, stable product performance (returned goods without quality problems within one year), sampling inspection once every 5 tons.

For the new insulating material of a qualified supplier or the insulating material or sample of the supplier for the first time, the sample should be sampled for the first time for type test, and the following five times of supply should be sampled. After passing the test, it can be transferred to another batch. Sampling. If the insulation material is found to be unqualified once, it shall be sampled according to the first batch of supply regulations. Each batch of insulating material must be accompanied by the supplier’s material warranty or test report.

Sampling method: take 2 bags or more per batch. Checkable items are tensile strength, elongation at break, dielectric strength, volume resistivity, volume resistivity at 80°C, oxygen index and density.

For the performance that cannot be detected, it shall be accepted according to the manufacturer’s test report or warranty. The packaging insulation material is packed in plastic film bags and external PP braid/kraft paper composites. The net weight of each bag is 25±0.2kg, but no negative deviation per ton is allowed.

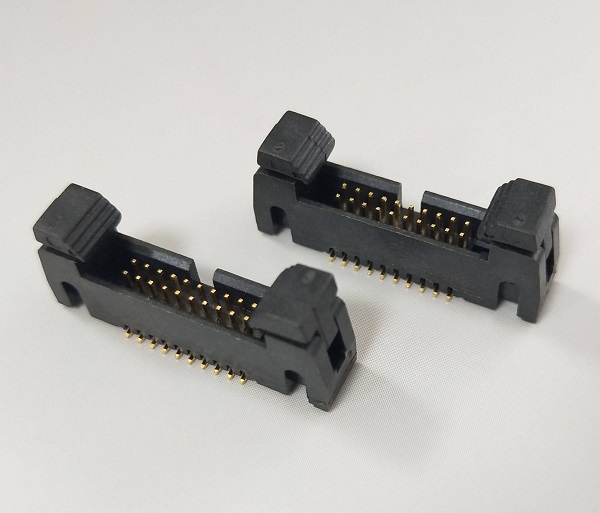

EJECTOR HEADER CONNECTOR PITCH:1.27MM(.050″) DUAL ROW SMT

Board-to-board connector insulating material packaging must be marked with: manufacturer’s name, material model and name, production date, net weight, and product qualification certificate. When the electronic wire connector insulation material is brought into the factory, it should be accompanied by the manufacturer’s quality assurance certificate or quality inspection report. When first supplying, the manufacturer must attach the type test report of the legal inspection department. During normal supply, the manufacturer must provide the type test report of the statutory inspection department of that year every two years.

The insulating material of the transport board-to-board wire connector should not be exposed to sunlight or rain, and the packaging should not be damaged.

The insulation material of the storage board-to-board wire connector should be stored in a clean, cool, dry and ventilated warehouse. The storage period is 12 months from the production date