Why should board-to-board connectors be tested in salt spray environment

Why should board-to-board connectors be tested in salt spray environment? Salt spray environment mainly refers to the application environment of medical device connectors, electric vehicle connectors and underwater application equipment. Under normal circumstances, the salt spray environment refers to the salt spray environment formed by 5% salt solution. Usually, this environment can effectively evaluate the equipment or components directly exposed to the sea or land salt environment, which is not a real environment. Normal exposure time is between 48 hours and 96 hours.

Salt spray test is usually used in underwater environment and to evaluate the corrosion resistance of metal connector shell (for example, to verify the corrosion protection effect of nickel coating on the surface of zinc alloy die casting). The performance of exposed parts is confirmed by checking DWV and insulation resistance, so that the shell seal is effective.

Salt spray test is sometimes used to evaluate automobile connectors. When automobiles or trucks are walking, these board-to-board connectors may come into contact with splashed water on tires, especially after snow falls in winter in northern China, salt will be applied on roads to accelerate snow melting. Generally, these connectors should be tested by salt spray to verify their corrosion resistance. The verification standard is to check the reliability of contact resistance, not to evaluate it by checking the appearance. In many cases, these connectors should be used together with sealing rings to improve its salt spray resistance.

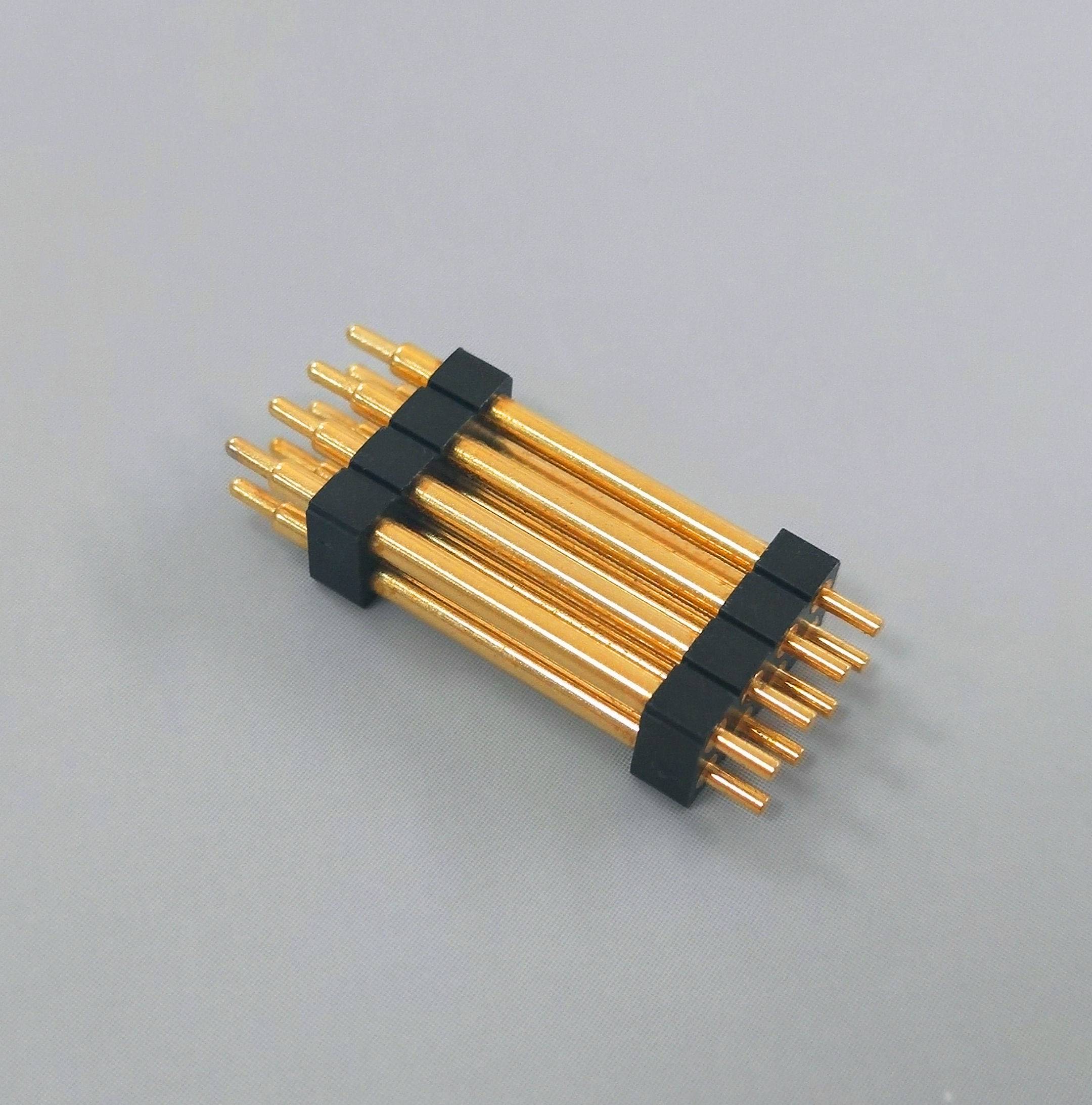

SPRING LOADED CONNECTORS PITCH:2.54MM DUAL ROW GOLD PLATED:1U” DIP TYPE