How to select a board to board connector?

1.Lead, spacing

Pin number and pin spacing are the basic basis of connector selection.The number of pins to choose depends on the number of signals to be connected.For some patch connectors, such as patch pins, the number of pins should not be too much.Because in the placement machine welding process, due to the effect of high temperature, the connector plastic may be subjected to heat deformation, central uplift, resulting in pin virtual welding.

Nowadays, electronic devices are developing towards miniaturization and precision, and the pin spacing of connectors also goes from 2.54mm to 1.27mm and then to 0.5mm.The smaller the pin spacing, the higher the production process requirements.Pin spacing should be determined by the company’s level of production technology, not blind pursuit of small spacing.

2.Electrical performance

The electrical properties of the connector mainly include: limit current, contact resistance, insulation resistance and electrical strength, etc.Pay attention to the limit current of the connector when connecting the high-power power supply;When transmitting high frequency signals such as LVDS and PCIe, the contact resistance should be paid attention to.Connectors should have low and constant contact resistance, usually dozens of m Ω to hundreds of m Ω.

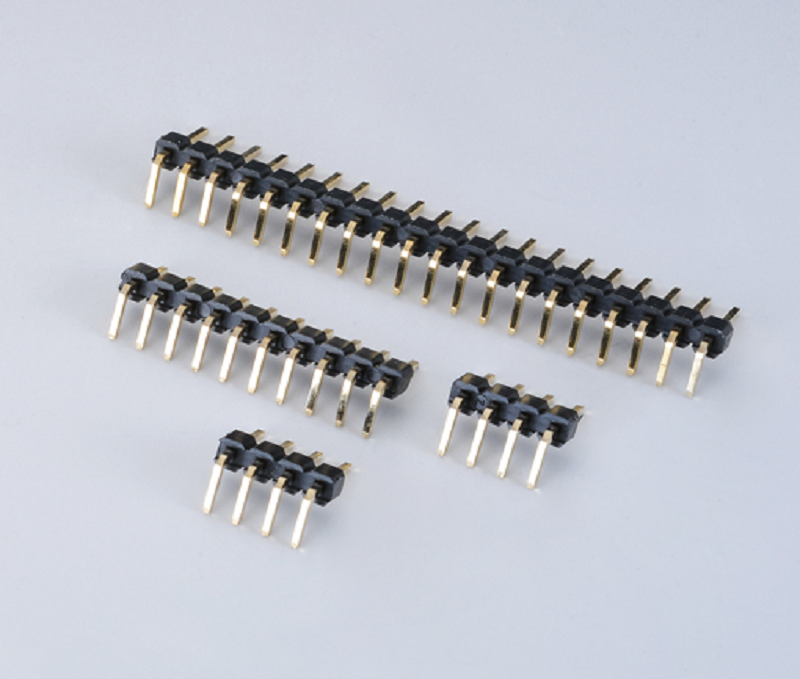

PIN HEADER PITCH:1.0MM(.039″) DUAL ROW RIGHT ANGLE TYPE

3.Environment performance

The environmental performance of the connector mainly includes: temperature resistance, humidity resistance, salt spray resistance, vibration, impact, etc.According to the specific application environment selection.If the application environment is more humid, for the connector moisture resistance, salt spray resistance requirements on the high, to avoid the connector metal contact corrosion.In the field of industrial control, the anti – vibration impact performance of the connector is required to be high, so as not to fall off in the process of vibration.

4.Mechanical properties

The mechanical properties of the connector include pulling force, mechanical anti – freeze and so on.Mechanical anti-freeze is very important to the connector, once inserted in reverse, it is likely to cause irreversible damage to the circuit!

Pullout force is divided into insertion force and separation force.There are provisions in the relevant standards for super large insertion force and super small separation force. From the perspective of use, the insertion force should be small and the separation force should be large.Too little separation force will reduce the reliability of contact. However, for connectors that often need to be plugged or unplugged, too much separation force will increase the difficulty of pulling out and reduce the mechanical life.