Structural features and functions of wire-to-board connectors

In the wire-to-board connector, the insulating base of the connector is provided with a wire receiving groove for the preset wire to be placed in and positioning, and a joint for butting with the external connector is formed on one side of the insulating base, and a plurality of connectors are provided on the joint. There are two contact terminals positioned around, and one end of each contact terminal is provided with a welding part passing through the insulating base to the wire receiving groove and connected with the preset wire, characterized in that the plurality of contact terminals are in a horizontal U shape , The bottom of each contact terminal is provided with a long-distance welding part positioned on the inner surface of the wire receiving groove, and the contact terminal is also provided with a contact part that is bent upward and reverse and surrounds the periphery of the connector. Welding connection. With this structural design, the height of the connector can be effectively reduced, the contact terminals are fastened firmly, the contact area is easier to grasp, the contact effect is good, and the effect of low impedance can be achieved.

When the printed circuit board in the system and electronic equipment receives/transmits the output power of the signal, it needs to be connected to the outside of the substrate. In many cases, there is a certain distance between the printed circuit board and the substrate, which requires wires to connect. Long-distance connections can be achieved by soldering wires to the substrate. However, for functional considerations, multi-pin wire-to-board connectors are usually used for connection.

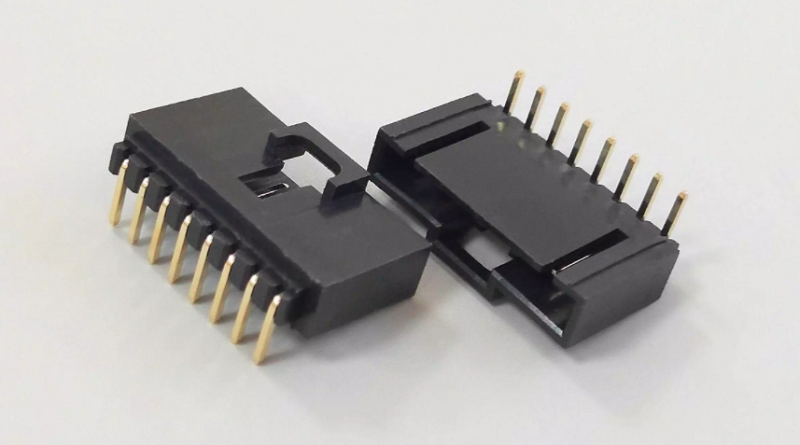

The structure of the wire-to-board connector is very simple: place the electrodes (contacts) in the shell (plastic shell). There are two types of contacts: stick or chip “plug” and “socket”. Squeeze the plug completely into the socket and cover it to achieve “matching”. Generally speaking, the socket is connected to the wire and the plug is connected to the substrate, but this can be reversed depending on the usage. The connection of wires and contacts is generally achieved using “pressure bonding” technology, such as crimp terminals. You can also use “pressure welding” to connect wires and contacts. Pressure welding technology is used for low current connections, allowing full connection by simply connecting insulated wires to contacts. Although this method is convenient, the durability may be reduced. The above two technologies can avoid overheating caused by soldering technology and protect the connection from damage. In addition, since the airtight connection area is not exposed to the air, the connection can be kept stable.